Frequently Asked Questions

We have questions and answers to help you decode the terminology and the fundamentals of mouldmaking and casting.

We have questions and answers to help you decode the terminology and the fundamentals of mouldmaking and casting.

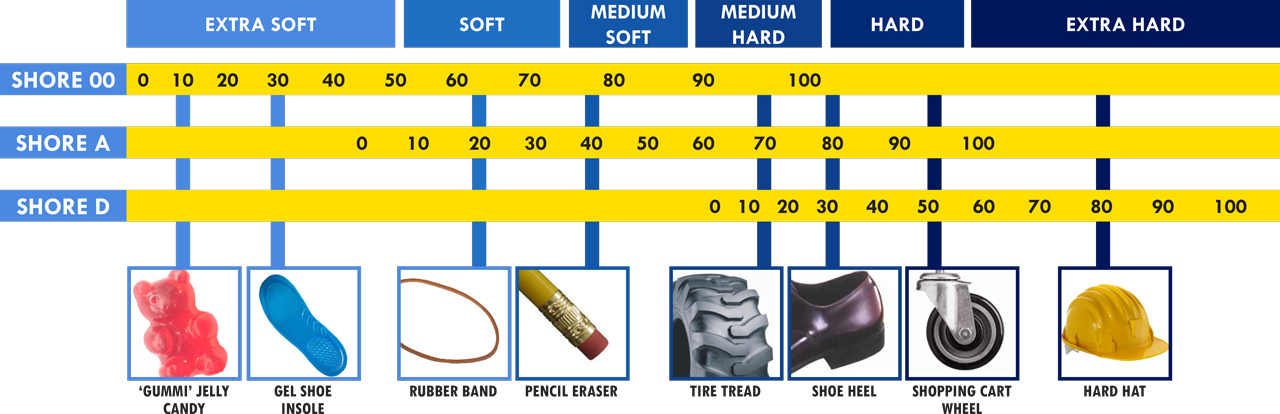

Shore hardness is a measurement of the resistance a material has to indention. There are distinct shore hardness scales for measuring the hardness dissimilar materials ( flexible rubbers inflexible plastics, and supersoft gels instance ). These scales were design so that people can investigate these materials and have a common point of reference.

Shore hardness becomes an important factor when considering which mold rubber you should choose for making a mold of your original. For example, you would not chose a rubber with a durometer of 70a to make a mold of a fragile model with thin, protruding arms bent at opposing angles. A 70A rubber (as hard as a car tyre) is stiff and would not offer enough flexibility to extract this model without breaking it. A better choice would be a shore 30a rubber or softer that would offer enough flexibility to easily extract the model.

Following is an example Shore hardness scale showing references of real-world objects.

The Shore 00 Hardness Scale measures rubbers and gels that are very soft.

The Shore A Hardness Scale measures the hardness of flexible mold rubbers that range in hardness from very soft and flexible, to medium and somewhat flexible, to hard with almost no flexibility at all. Semi-rigid plastics can also be measured on the high end of the Shore A Scale.

The Shore D Hardness Scale measures the hardness of hard rubbers, semi-rigid plastics and hard plastics.